made of borosilicate glass "extra-hard", long types

KLINGER transparent glasses are manufactured from “extra-hard” borosilicate glass. The surfaces on both sides are finely ground and polished to ensure optimal transparency.

applications:

In steam service above 35 bar and with media with a high pH-value KLINGER transparent glasses must be protected by a mica shield on the side facing the medium chamber. Transparent glasses should always be chosen for contaminated, viscous or corrosive media. Within the given service limitations they may be used for all media except steam at pressures up to 340 bar or temperatures up to 400°C.

technical data:

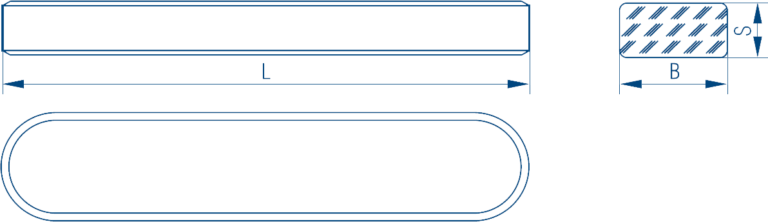

Transparent glasses A, B, H, TA 28

Overall dimensions (mm)

| Size | Type A | Weight g/piece | Type B | Weight g/piece | Type H | Weight g/piece | Type TA 28 | Weight g/piece | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | B | S | L | B | S | L | B | S | L | B | S | |||||

| I | 115 | 30 | 17 | 122 | 115 | 34 | 17 | 137 | – | – | – | – | 113 | 27.6 | 16.8 | 114 |

| II | 140 | 30 | 17 | 152 | 140 | 34 | 17 | 172 | 140 | 34 | 22 | 218 | – | – | – | – |

| III | 165 | 30 | 17 | 176 | 165 | 34 | 17 | 204 | 165 | 34 | 22 | 260 | 163 | 27.6 | 16.8 | 168 |

| IV | 190 | 30 | 17 | 211 | 190 | 34 | 17 | 238 | 190 | 34 | 22 | 302 | 188 | 27.6 | 16.8 | 194 |

| V | 220 | 30 | 17 | 250 | 220 | 34 | 17 | 280 | 220 | 34 | 22 | 357 | 218 | 27.6 | 16.8 | 226 |

| VI | 250 | 30 | 17 | 280 | 250 | 34 | 17 | 317 | 250 | 34 | 22 | 400 | 248 | 27.6 | 16.8 | 258 |

| VII | 280 | 30 | 17 | 314 | 280 | 34 | 17 | 356 | 280 | 34 | 22 | 460 | 278 | 27.6 | 16.8 | 290 |

| VIII | 320 | 30 | 17 | 360 | 320 | 34 | 17 | 407 | 320 | 34 | 22 | 530 | 318 | 27.6 | 16.8 | 334 |

| IX | 340 | 30 | 17 | 387 | 340 | 34 | 17 | 430 | 340 | 34 | 22 | 562 | 338 | 27.6 | 16.8 | 356 |

| X | – | – | – | – | 370 | 34 | 17 | 480 | – | – | – | – | – | – | – | – |

| KLINGER gauge glasses Applicational range transparent glasses | Type A 1) | Type B 1) | Type H | Type TA 28 4) | ||||

|---|---|---|---|---|---|---|---|---|

| bar | °C | bar | °C | bar | °C | bar | °C | |

| For media with no significant glass attack, e..g. oils, hydrocarbons | 240 160 0–10 | 120 400 430 | 290 200 0–10 | 120 400 430 | 340 230 0–10 | 120 400 430 | – – – | – – – |

| For media with significant glass attack, e..g. saturated steam, HPHW, alkalis | 2) 35 70 | 243 300 | 2) 35 85 | 243 300 | 2) 42 85 | 253 300 | 3) 120 180 | 324 356 |

1) Glass types to OeNORM M 7354 or DIN 7081.

2) For steam pressures above 35 bar we recommend the use of transparent glasses with mica shields.

3) For steam pressures above 120 bar only TA 28 glasses. size I. may be used.

4) TA glasses may only be used with mica shields