made of borosilicate glass "extra-hard", long types

The side facing the medium chamber is provided with moulded grooves set at 90° angles. The moulding process increases the resistance of the glass grooves to wear; the “skin” which the glass attains during moulding gives it maximum smoothness and hardness. This makes it extremely resistant to the attack of boiler water.

applications:

Up to 35 bar saturated steam, reflex glasses provide the optimum solution: they are corrosion resistant and provide an absolutely clear indication. Reflex glasses can be used with all media except steam at service conditions up to 400 bar or temperatures up to 400 °C.

technical data:

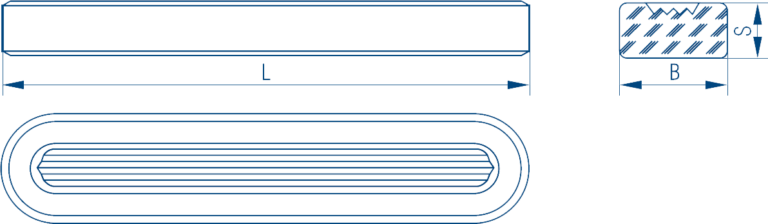

Reflex glasses A, B, H

Overall dimensions (mm)

| Size | Type A | Weight g/piece | Type B | Weight g/piece | Type H | Weight g/piece | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L | B | S | L | B | S | L | B | S | ||||

| 0 | – | – | – | – | 95 | 34 | 17 | 110 | – | – | – | – |

| I | 115 | 30 | 17 | 118 | 115 | 34 | 17 | 132 | 115 | 34 | 22 | 176 |

| II | 140 | 30 | 17 | 146 | 140 | 34 | 17 | 162 | 140 | 34 | 22 | 214 |

| III | 165 | 30 | 17 | 176 | 165 | 34 | 17 | 195 | 165 | 34 | 22 | 254 |

| IV | 190 | 30 | 17 | 200 | 190 | 34 | 17 | 228 | 190 | 34 | 22 | 294 |

| V | 220 | 30 | 17 | 237 | 220 | 34 | 17 | 264 | 220 | 34 | 22 | 344 |

| VI | 250 | 30 | 17 | 265 | 250 | 34 | 17 | 301 | 250 | 34 | 22 | 392 |

| VII | 280 | 30 | 17 | 303 | 280 | 34 | 17 | 338 | 280 | 34 | 22 | 445 |

| VIII | 320 | 30 | 17 | 334 | 320 | 34 | 17 | 387 | 320 | 34 | 22 | 503 |

| IX | 340 | 30 | 17 | 359 | 340 | 34 | 17 | 410 | 340 | 34 | 22 | 536 |

| X | – | – | – | – | 370 | 34 | 17 | 461 | – | – | – | – |

| KLINGER gauge glasses Applicational range reflex glasses | Type A 1) | Type B 1) | Type H | |||

|---|---|---|---|---|---|---|

| bar | °C | bar | °C | bar | °C | |

| For media with no significant glass attack, e..g. oils, hydrocarbons | 400 150 0–10 | 120 400 430 | 265 180 0–10 | 120 400 430 | 300 200 0–10 | 120 400 430 |

| For media with significant glass attack, e..g. saturated steam, HPHW, alkalis | 35 | 243 | 35 | 243 | 2) 42 | 253 |

1) Glass types to OeNORM M 7354 or DIN 7081.

2) For steam pressures above 35 bar we recommend the use of transparent glasses with mica shields.