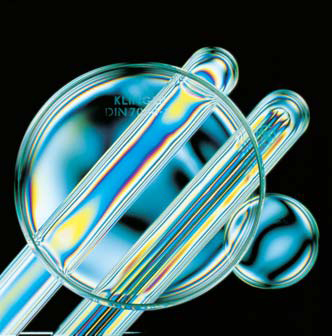

Borosilicate Gauge & Sight Glasses

The gauge glass is the most important component of the liquid level gauge.

The quality of a sight (gauge) glass depends mainly on the chemical composition and mechanical strength of the glass material.

Constant glass quality is provided through glass analyses and acid/alkali tests. The mechanical strength is attained through thermal pre-stressing.

KLINGER gauge glasses are suitable for installation in liquid level gauges of almost any make.

Exclusively made of “extra-hard” borosilicate glass which is subsequently heat-treated.

KLINGER gauge glasses have high mechanical strength and are exceptionally resistant to alkalis, acids and boiler water (within the service limitation). KLINGER’s glass testing laboratory carries out continuous quality control tests for purity of glass, flaws in glass, dimensional accuracy, etc.

This ensures the high quality standard of all KLINGER gauge glasses. KLINGER reflex and transparent glasses are manufactured according to the most varied international standards.

Fields of application:

- Oil refineries

- Petro-chemical plants

- Pharmaceutical manufacture

- Chemical processing

- Mechanical engineering, especially manufacture of boilers and storage vessels

- Food and beverage industry

- Water engineering

- Pulp and paper industry

- Textile industry

- Marine engineering

- Nuclear engineering

Quality Control

Standards

KLINGER manufactures reflex and transparent glasses in series to the following standards:

- OeNORM M 7354 (long gauge glasses)

- DIN 7081 (long gauge plate glasses)

- JIS B 8211 (Japanese Industrial Standard)

- OMV-Spez. H 2009 (OMV-AG, Vienna)

- MIL-G-16356 D (US-Navy-Ships)

- Esso Eng. Spec. 123 (Esso Research & Engineering Co. – New Jersey)

- S.O.D. Spec. 123 (Standard Oil Development Company – New Jersey)

- BS 3463 (British Standard Institution)